WHAT WE DO

Services

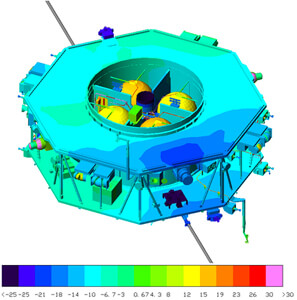

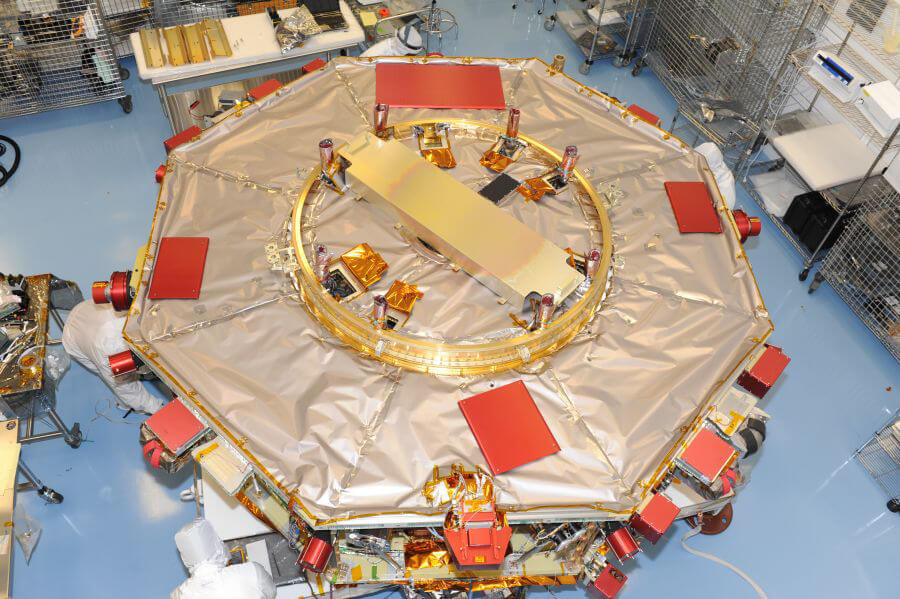

Spacecraft Thermal Control System (TCS) Design and Analysis

Vertex Aerospace utilizies state-of-the-art industry standard thermal analysis tools and techniques to design, analyze and develop integrated thermal control solutions for our customers. Vertex Aerospace thermal engineers have expertise and extensive knowlege in developing a passive, active or hypbrid TCS. Spacecraft typically have a wide range of thermal requirements and interfaces to control. Vertex Aerospace is committed to providing expertise in spacecraft thermal design that meets and where applicable exceeds our customer's requirements and expectations.

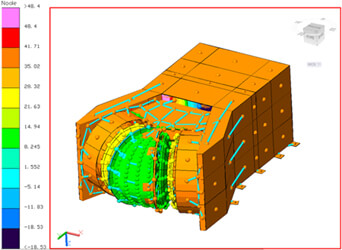

Instrument Thermal Control System (TCS) Design and Analysis

Vertex Aerospace has extensive experience working with universities, private industry and government agencies in the developing thermal control systems for instruments. Instrument TCS requirements are typically what drives the spacecraft interface requirements. Vertex Aerospaceunderstands the importance that the instrument thermal control. Most missions rely on the success of their instruments and instrument components. Similar designing a spacecraft TCS, Vertex Aerospace utilizies state-of-the-art industry standard thermal analysis tools and techniques to design, analyze and develop integrated thermal control solutions for the instrument. Vertex Aerospace thermal engineers have expertise and extensive knowlege in developing a passive, active or hypbrid instrument thermal control systems. Instruments typically have a stringent set of thermal requirements and interfaces to achieve the desired preformance. Vertex Aerospace is committed to providing expertise in instrument thermal design that meets and where applicable exceeds our customer's requirements and expectations.

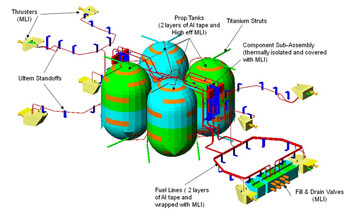

Propulsion Thermal Control System (TCS) Design and Analysis

Vertex Aerospace has proven experience in developing state-of-the-art thermal control for spacecraft propulsion systems. Working closely with the Propulsion Product Design Lead (PDL) the Vertex Aerospace thermal engineers design, analyze and implement thermal control system hardware to ensure all components of the Propulsion subsystem are maintained within their design temperature requirements during all phases of the mission. Whether it's a pressure transducer, fill and drain valve, propulsion line, propulsion tank or thruster, the Vertex Aerospace thermal engineers have the knowledge and expertise to develop, analyze and implement a thermal control system that meets and where applicable exceeds our customer's requirements and expectations.

Battery and Power Subsystem Temperature Control Design and Analysis

Vertex Aerospace has designed, analyzed and developed thermal control for several NASA programs and a variety of battery types and configurationas. Lithium Ion batteries have become the aerospace industry standard, however, the Vertex Aerospace thermal engineers have experience supporting the thermal control for Nickel Cadmium (NiCd) and Nickel Metal Hyrdride (NiMH) batteries as well. In addition, the Vertex Aerospace thermal engineers work closely with the Power Subsystem Product Design Leads (PDL) and battery vendors to design, analyze and implement the thermal control system hardware to ensure all components of the Power Subsystem are maintained within their design temperature requirements during all phases of the mission.

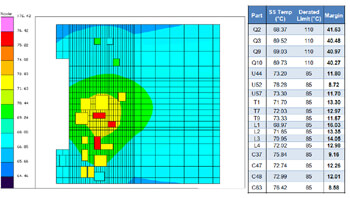

Electronic PCB Thermal Design and Analysis

Vertex Aerospace has designed and analyzed a large variety of printed circuit boards (PCB) (a.k.a. Printed Wiring Board - PWB) for aerospace and industry. Whether the electronics are being designed for space applications where air cooling is not available or in an aircraft where high temperature air flow is a concern, the Vertex Aerospace thermal engineers have proven experience in the design, analysis and development of thermal control solutions for our customers. We utilize state-of-the-art industry standard thermal analysis tools and techniques and have extensive knowledge and experience in the design and analysis of multi-layer circuit boards. The Vertex Aerospace thermal engineers work closely with the electronic engineers to understand the requirements, PCB layout and mechanical attachments. Whether it's copper planes, copper traces, thermal filler or thermal vias, the Vertex Aerospace thermal engineers will develop the thermal control solution to fit the application and budget of their customer.

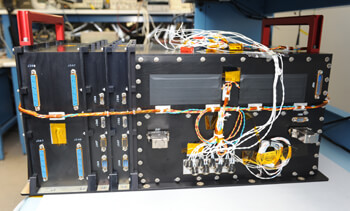

Avionics Box Thermal Design and Analysis

Vertex Aerospace has proven experience in the thermal design, analysis and testing of aerospace avionic boxes. Whether the electronics are being designed for space applications where air cooling is not available or in an aircraft where high temperature air flow is a concern, the Vertex Aerospace thermal engineers have proven experience in the design, analysis and development of thermal control solutions for our customers. We utilize state-of-the-art industry standard thermal analysis tools and techniques and have extensive knowledge and experience in the design and analysis of high power avionic boxes. The Vertex Aerospace thermal engineers work closely with the mechanical and electrical engineers to understand the box requirements, PCB configuration and mechanical attachments. Whether it's placing thermostatically controlled heaters on the box, or placing a thermal filler such as Nusil, ChoTherm or ChoSeal at the box mounting interface, the Vertex Aerospace thermal engineers will develop the thermal control solution to fit the application and budget of their customer.

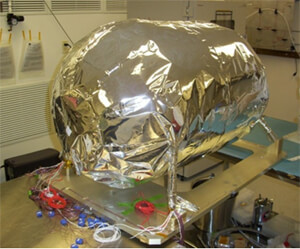

Multi Layer Insulation (MLI) Custom Design

Vertex Aerospace has designed, analyzed and developed custom Multi-Layer Insulation (MLI) solutions consisting of many shapes and sizes for government and industry. Vertex Aerospace and with the assistance of our MLI fabrication partner can design, analyze and test the performance of the MLI for our customer. Vertex Aerospace thermal engineers have the knowledge and expertise to develop, analyze and implement high efficiency MLI that meets and where applicable exceeds our customer's requirements and expectations.

Thermal Vacuum and Thermal Balance Environmental Testing Design, Analysis and Support

Vertex Aerospace has extensive knowledge and experience in the integration and testing of thermal control hardware and verification of thermal control systems. Whether, it's an electronic box, instrument or spacecraft the Vertex Aerospace thermal engineers have the knowledge and expertise to develop the thermal vacuum (TV) and thermal balance (TB) test plans and test procedures to fit the application and budget of their customer. In addition, the Vertex Aerospacethermal engineers have proven experience in developing pre-test thermal models and performing detailed thermal analysis to understand and identify the test requirements and parameters needed to ensure a successful test program. Furthermore, the Vertex Aerospace thermal engineers use state-of-the-art thermal analysis tools and their experience to perform the important task of post thermal balance model correlation.